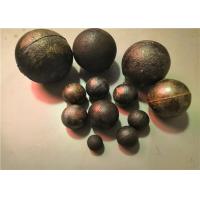

Jinan Dragon Steel Balls Co.,Ltd

Dragon Grinding Balls is a professional manufacturer of grinding

media balls.Owning more than 19 years working experience in

grinding media balls R & D, production, quality control, sales,

export,service and project solutions.

Dragon Grinding balls production line covers hot rolling balls

,forged steel balls, cast iron balls, cylpebs ,grinding rods ,

ceramic grinding balls .high aluminum bricks. Our grinding balls

are widely used in grinding for ball mill, rod mill, it is used in

mining,cement plant, power plant and industry an so on.

Besides our Chinese domestic market, our grinding balls also have

been exported to Europ, Mid East, Africa, South America and Asia

countries. The service covers mining, cement plant and power plant

and after sales services.

We have mature technology and technics for grinding balls,also can

help our customers for producing line arrangement. Our balls'

quality is good and reliable. You are warmly welcome to establish

long term cooperation relationship with us!